- Company: PepperLawson Waterworks

- Industry: Water/Wastewater

- Location: Cypress, Texas

- Expected Completion Date: May 19, 2015

- Project Website

Last year my crew and I (please see me atop the headworks in Photo 1) at PepperLawson Waterworks (PLW) here in Houston built the Bridgeland Wastewater Treatment Plant Expansion for the Bridgeland Development in Cypress, Texas, just west of Houston. It was a 2.5 year project that added 1.5 million gallons a day (MGD) to the existing 0.6 MGD plant. That means the project enabled the plant to process more wastewater to accommodate the needs of the growing residential development.

The project involved constructing a 90-foot-diameter clarifier, aeration basins, several buildings, ultraviolet disinfection facilities, lift stations; installing blowers and other equipment and all the piping, electrical and accessories necessary for a functional 2.1 MGD plant. Much of the initial work was underground.

We also did a lot of other “dirt work” as well, expanding the onsite detention pond and constructing an underground pipeline running from the plant to an amenity lake about a quarter-mile away.

Most people don’t realize that a wastewater treatment plant not only processes sewer waste but can also help reduce drought conditions, help wildlife habitat and replenish a recreational lake. The Bridgeland project accomplished many positive attributes and benefited America in many ways! Not just the people that live and work in the area but also the migratory birds, local wildlife, flora and fauna. These are the reasons I feel so proud to have been a part of it.

What impact does this project have on America?

The owner of the wastewater treatment plant has one of the largest master planned communities under development in the Houston area in more than 30 years. Bridgeland Development is an 11,400-acre development for up to 65,000 residents and 18,000 single family homes in West Houston. Located within the boundaries of the Katy Prairie, the development is an environmental gem providing refuge and foraging for resident and migratory birds, mammals, reptiles and amphibians. Annually, Bridgeland’s Nature Fest offers a variety of educational and entertaining options for families in and around the Cypress area. Furthermore, the wastewater treatment plant’s owner is an active promoter of environmental care and awareness.

Bridgeland’s sensitive planners carefully designed infrastructure with the future in mind. These items include:

- • Unique Waterways—An over 900-acre system of interconnected lakes and streams adds not only aesthetic and recreational value but also functions as an efficient stormwater collection and conveyance system.

- • Innovative Hydrologic Design—A new hydrologic analysis process and design developed to tailor the waterway/drainage system to serve current and future needs and fully mitigate downstream impacts.

- • Unique Roadways—Neighborhood roundabout street designs and 25-ft street widths reduce the heat of the concrete and preserves green space.

- • Economical Majestic Bridges—Bridges built with pre-fabricated concrete culverts clad with brick instead of all brick saved $2 million.

- • Educational Opportunities—A signage system detailing indigenous plants and animals, flowers to attract butterflies and native plantings that minimize the need for frequent irrigation, fertilization and maintenance.

- • Wildlife-friendly structures that support the area’s bird, bat and butterfly populations, and lights with shields that direct the light to the ground reducing any negative effect on birds.

Bridgeland encompasses over a dozen separate municipal utility districts serving single-family residential, multi-family, and commercial developments with water supply and distribution, sewage collection and treatment, and stormwater drainage.

The project’s overall infrastructure includes:

- • > 800 acres of commercial and retail development

- • > 6,000 acres of residential development

- • > 3,000 acres of detention/amenity lakes, trails and parks

- • > 1,500 acres of landscape reserves and green-belt corridors

So again, the expansion of the Bridgeland Wastewater Treatment Plant had a critical impact not only on the human population but also on the birds, flora and fauna that inhabit this vast environmental habitat. Every gallon of water from the wastewater treatment plant is recycled into the lake. The wastewater treatment plant project is projected to reduce the use of recreational water by 70% annually, and drastically reduces the community’s dependence on groundwater, one of our nation’s fast-depleting natural resources.

What interesting obstacles or unusual circumstances did you overcome to complete the project?

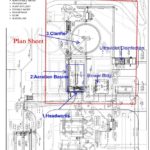

With an expansion project of the size of the Bridgeland plant, one of the most recognized tasks that PLW conquered was the coordination of all underground piping and components to all structures. Using the Plan Sheets and Specifications of Brown & Gay Engineers, Inc. (BGE) and after a thorough investigation of site and soil conditions, the PLW crew succeeded in maneuvering underground obstacles and constructing the expansion while keeping the plant operational and maintaining a constant water level in the lake.

Much of the difficult work in waterworks construction you never see. It is underground in the infrastructure. (See Photos 2 and 3.) In several areas within the plant, we administered a good amount of coordination with subcontractors and the field crews to make sure all underground piping (sewer, non potable [non drinkable water], and air) was successfully placed while avoiding all existing lines. (See 15 types of piping in Photo 2 PLW constructed).

The most critical construction involved these areas:

1) Effluent Lift Station: This structure takes treated water from the plant (non potable) and feeds the water to the lake. It is a concrete cylinder 34 feet in the ground and 24 feet in diameter. The most challenging aspect was installing this structure due to it being 34 feet in the ground. We did this by digging from the inside of the cylinder, essentially “sinking it” by displacing the dirt which causes the cylinder to sink inches at a time. This is a very slow process.

In addition, it had to exactly meet piping that needed to be placed also at 34 feet.

2) Effluent Holding Pond: This structure was a giant pond used to hold the non potable water. To build this, we needed to excavate 8,200 cubic yards of dirt and install a rubber liner to prevent water from seeping into the ground. It was one of the project’s critical tasks. This reuse of holding-pond-water helps maintain constant water levels in the Bridgeland Lake which is used for irrigation purposes in the common areas.

3) Aeration Basins: This massive, rectangular concrete structure is 101 feet long by 62 feet wide by 22 feet high. To build this structure, PLW made multiple concrete pours with huge forms, concrete pumps, and a huge crane. (See Photo 4.)

Constructing the aeration basin was the longest task on this job and it took five months to complete.

Overview of the Wastewater Treatment Process Basically, when you flush the toilet or brush your teeth, this “dirty water” goes down the drain and is carried to the treatment plant via the sewer pipes. At the treatment plant, there is a series of structures (headworks, aeration basin, clarifiers, disinfection facility) that treat the water. (See Photos 2, 3, 5, 7.) As the dirty water moves through these structures, it progressively gets cleaner. By the time it reaches the last structure, the water is clean enough to replenish the lake.

The first stage of treatment is at the Headworks (see my photo with some of our crew standing atop the Headworks structure in Photo 8) then it flows into the aeration basin, then into the circular clarifier. In the clarifier, water is separated and enters the filter to go to the ultraviolet disinfection facility. (See Plan Sheet Photo 2.) From the ultraviolet facility, the disinfected water ultimately goes to the onsite Holding Pond. From the Holding Pond, the water can be used for Cypress Creek to irrigate the Bridgeland lake system.

Additional and necessary construction were the Blower and Electrical Buildings where PLW installed the giant blowers (See Photo 7) and electrical switchgear, respectively.

What dangers and risks did you encounter, and describe any extraordinary methods used to keep workers safe?

Excavation always involves risks. As described in #3, the coordination necessary in accurately placing the various types of pipe (See Plan Sheet Photo 2) was extraordinary.

In order to bring the new expansion of the plant in service, PLW strategically planned and coordinated with the Owner and plant operators to create an hourly time schedule for the “Shutdown.” There had to be such a “Shutdown” or transition to “Tie in” the existing facility with the new plant. The shutdown had to be strategically timed so that the whole plant was not out of service. It was timed during the low period of the day from 9 am to 3 pm when people were away from their homes.

How did you leverage new technologies to work faster and reduce waste?

Prior to bringing the new expansion plant in service, PLW performed a 7-Day Functional Test.

The previous wastewater treatment plant in the Bridgeland community used chlorine as a traditional method to treat the water before it left the Treatment Plant. By State law, the minimum time for the effluent to be in contact with the chlorine is 20 minutes to achieve a specific level of treatment. Instead of chlorine, we used ultra-violet light technology as a disinfection technique. (Ultraviolet Light is the same light that makes black-light posters glow or causes sunburn when you are outside without sunscreen.) By using this technology, the recently completed 2.1 MGD WWTP reduces the effluent processing time from 20 minutes of contact time to taking only a few seconds. This results in a more efficient overall treatment plant system.

Additionally, the treatment process allows us to reuse the water as opposed to wasting it. Prior to this technology being implemented, all wastewater plant effluent was discharged into the adjacent Cypress Creek which eventually flows out to the Gulf of Mexico. Now, with the new 2.1 MGD plant online, 100% of this effluent is captured and pumped back to the community lake system to be re-used. As a result, the community no longer needs large volumes of fresh groundwater to replenish its lake system, but instead can rely on the effluent reuse.